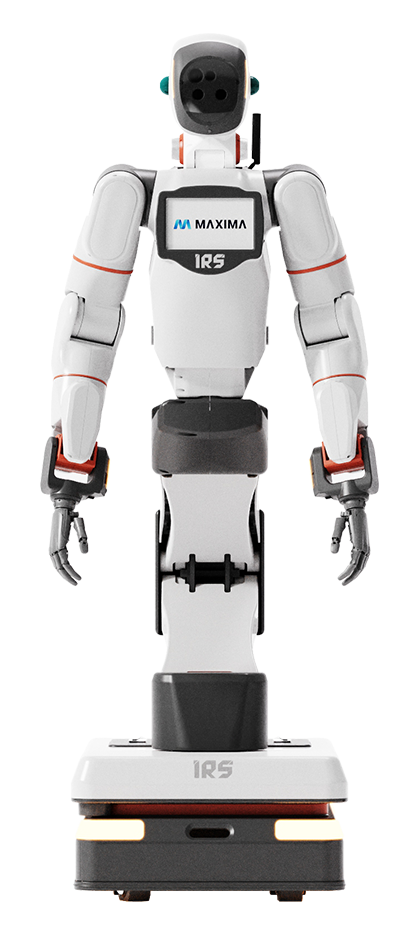

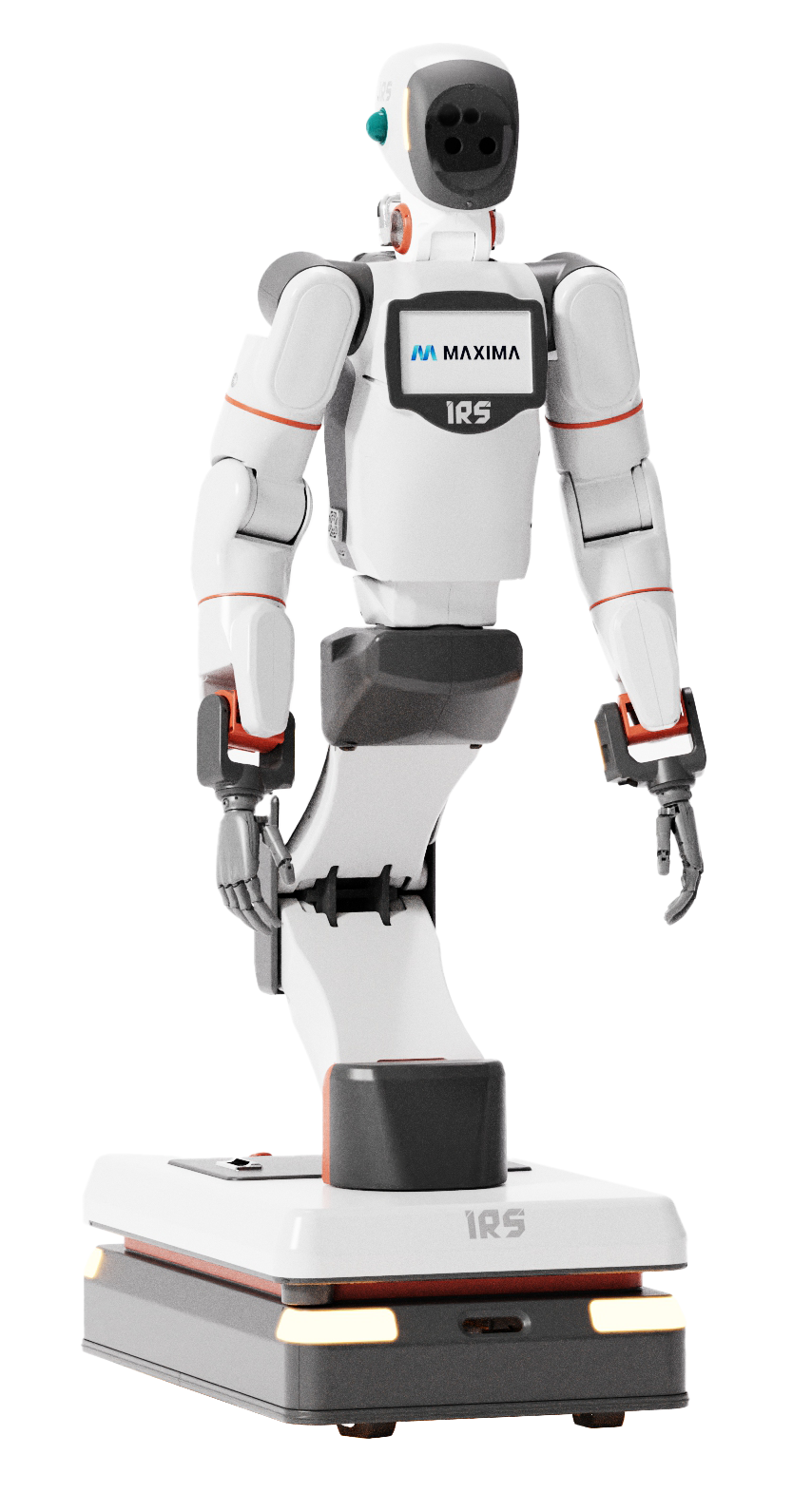

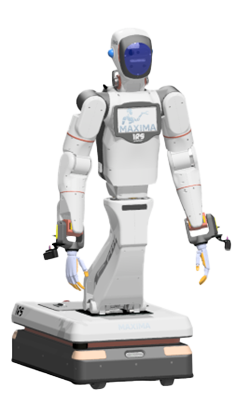

Blending into a human-centered work environment

Realizing the modular mobile manipulation robot 'Physical AI'

Maximizing all industrial sites where humans and robots coexist

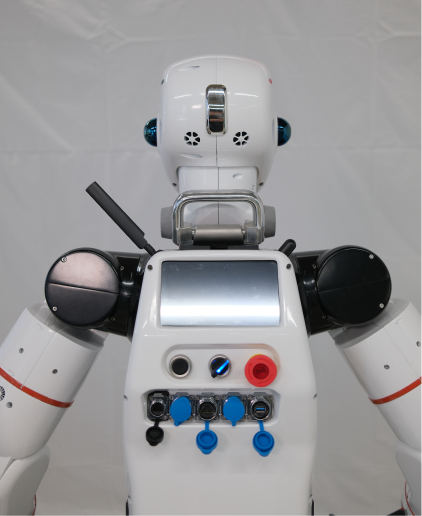

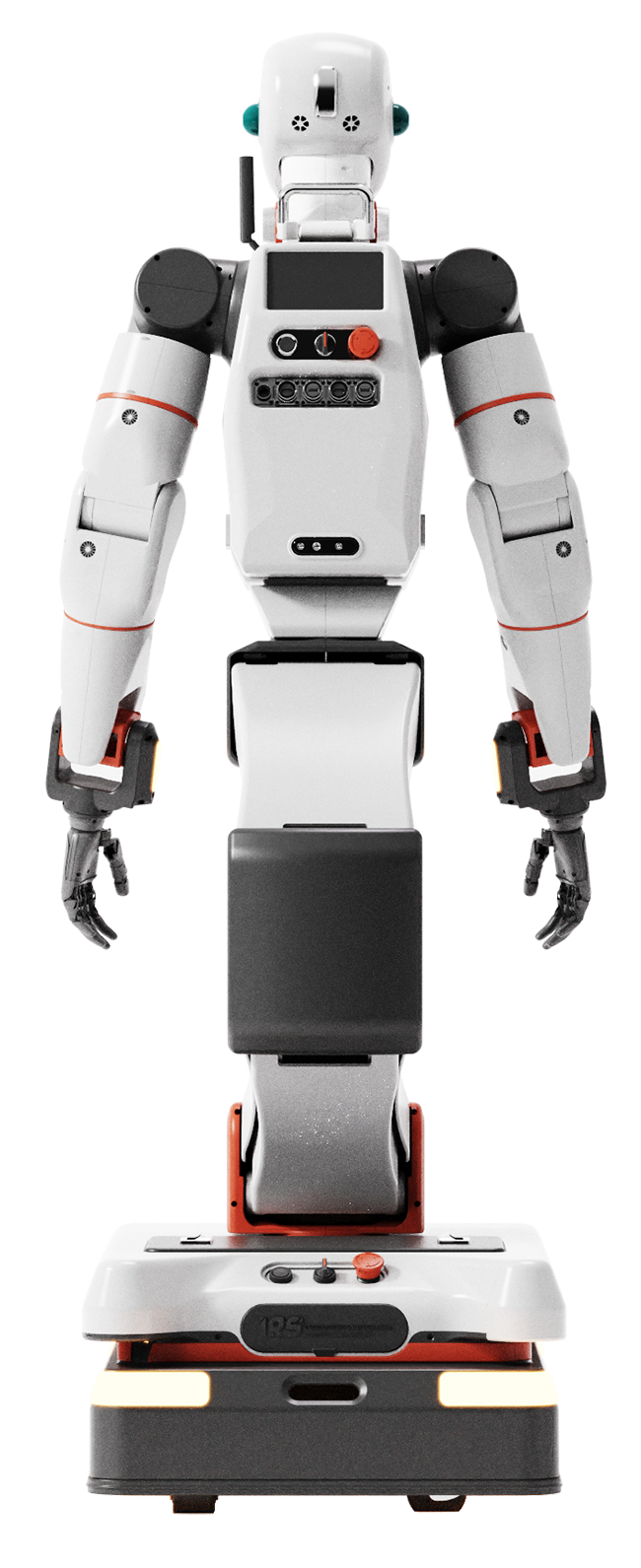

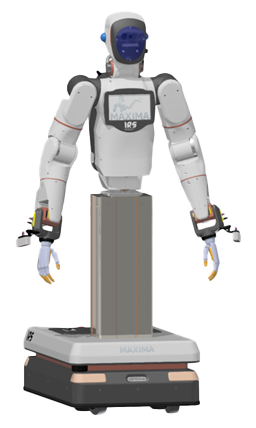

| Dimension (W X T X H) | 586mm X 980mm X 1,919mm | |

|---|---|---|

| Degree of freedom | Total | 21 |

| Head | 2 | |

| Torso | 3 | |

| Arm | 7 | |

| Under body | 3 | |

| Hand | 6 | |

| Arm | Single Arm Payload | 10kg |

| Repeatability | ±0.5mm | |

| Power | Charging time | 2h |

| Operation duration | 5h | |

| Source | 70Ah | |

| Mobile | Drive type | Differential Drive |

| Maximum Speed | 1.2 m/s (Peak 2m/s) | |

| Onboard computer (ApplicationPC) |

Nvidia Thor / Nvidia Jetson OrinNano | |

| Safety Functions | Self-collision avoidance, Task space limit, Fall prevention, Torque limit, Position error, Collision detection | |

| AI integration | Teleoperation, Data collection, Learning with dexterous hand and gripper, Etc… | |

-

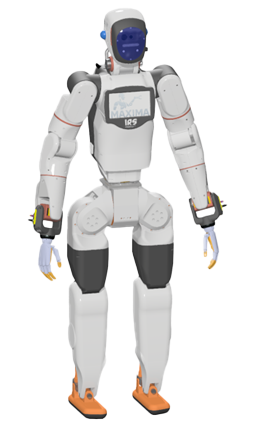

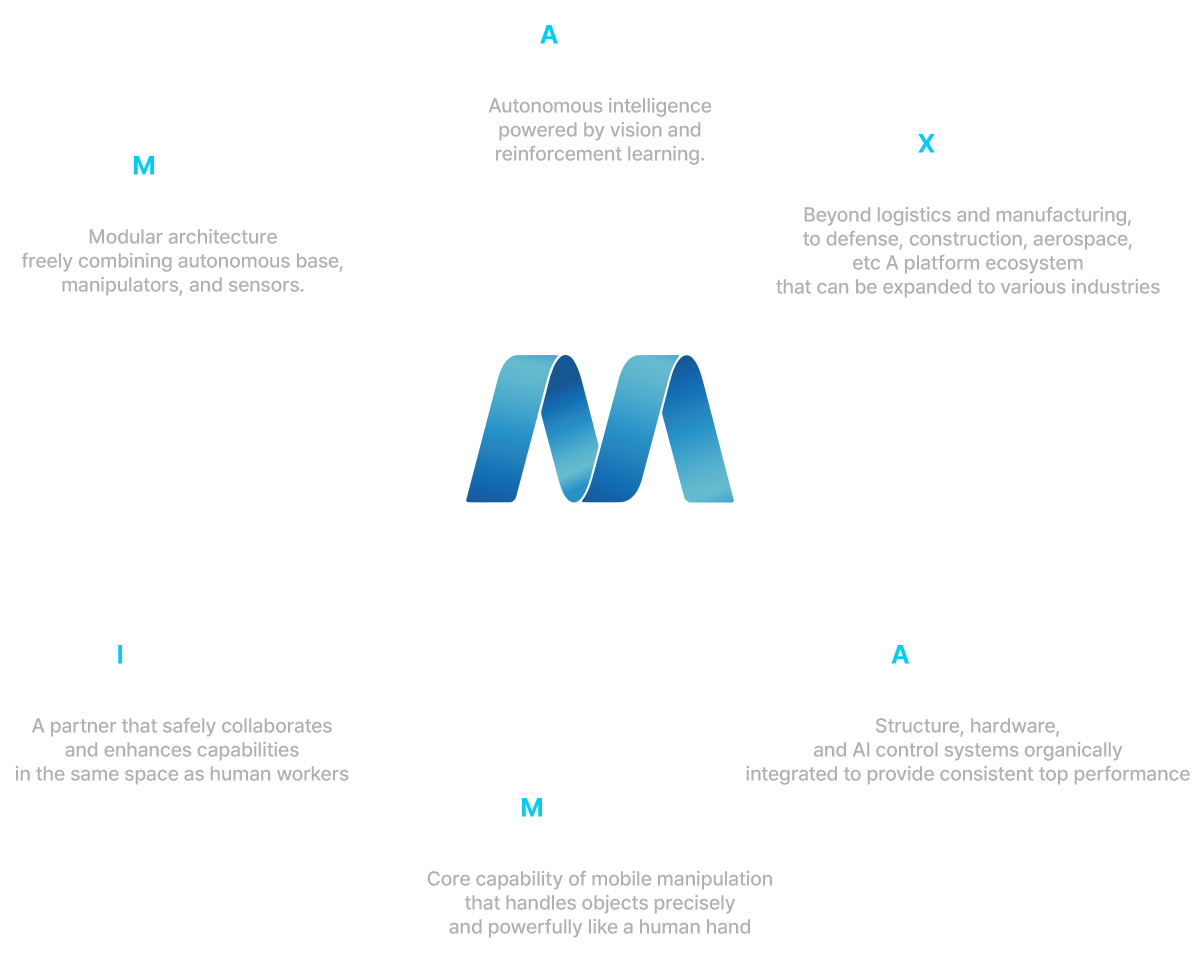

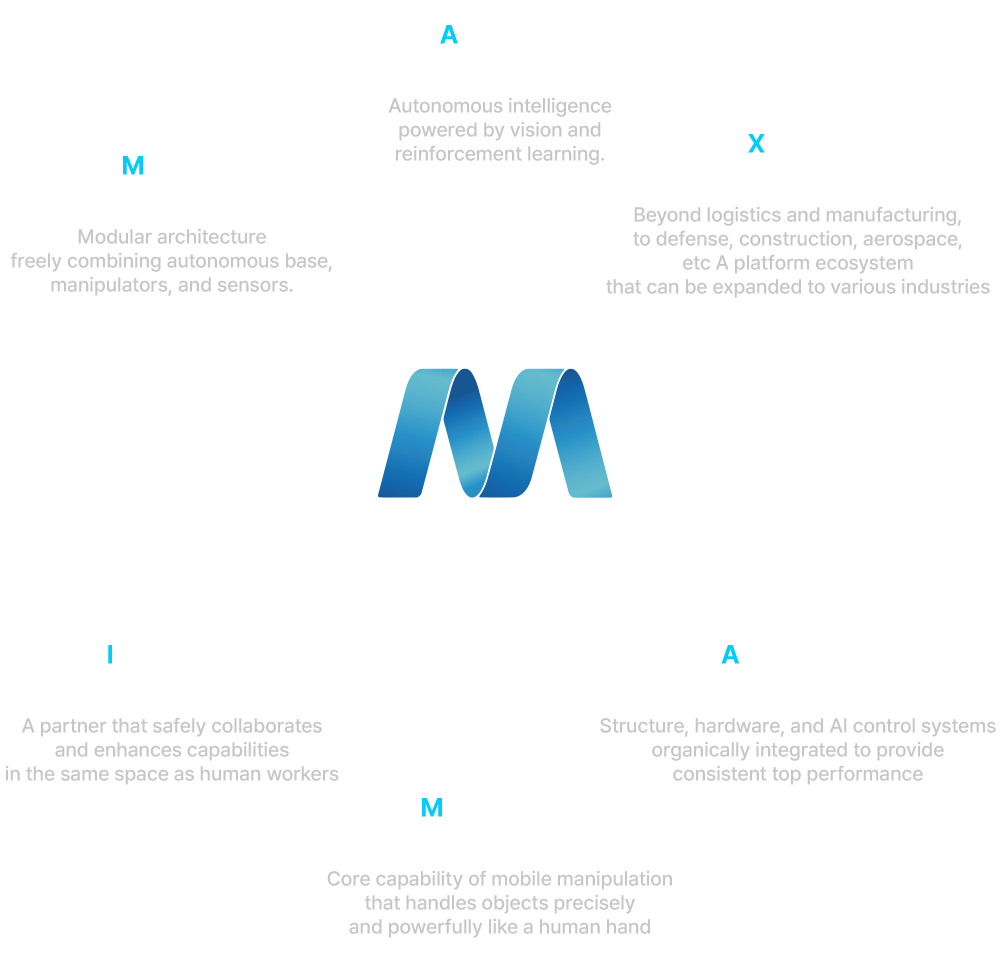

AI-driven Intelligent System

Autonomous intelligence powered

by vision and reinforcement learning. -

Modular Structure

Modular architecture freely

combining autonomous base,

manipulators, and sensors. -

eXandable scalability

Beyond logistics and manufacturing,

to defense, construction, aerospace, etc

A platform ecosystem that can be expanded to various industries -

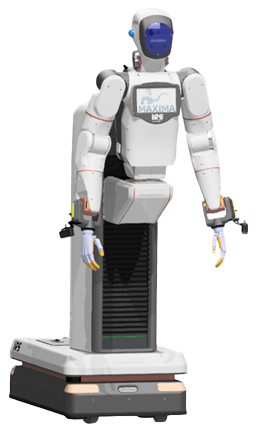

Architecture Integrated Structure

Structure, hardware, and AI control systems

organically integrated to provide consistent top performance -

Manipulation Skilled Work

Core capability of mobile manipulation that handles objects precisely and powerfully like a human hand

-

Interactive Interaction

A partner that safely collaborates and enhances capabilities

in the same space as human workers

Modular Mobile Manipulation

Customized configuration according to field requirements

Combination of mobile, manipulator, work tools, sensors, etc.

Humanoid for Physical AI

Brownfield that can move without changing existing facilities

Complete automation in the factory

Unified AI Core & FMS

Multiple heterogeneous robots (MMR, humanoid, etc.)

Real-time optimization of integrated control workflows